The "Voltage Sentinel" of Electric Vehicles: How Hall Voltage Sensors Prevent Overloads in High-Voltage Systems.

The "Voltage Sentinel" of Electric Vehicles: How Hall Voltage Sensors Prevent Overloads in High-Voltage Systems.

1. The Critical Need for Isolation Monitoring in EV High-Voltage Systems

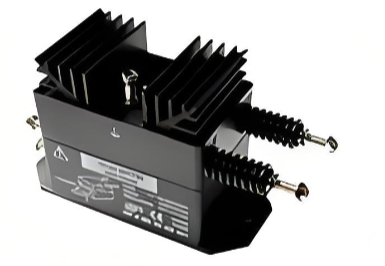

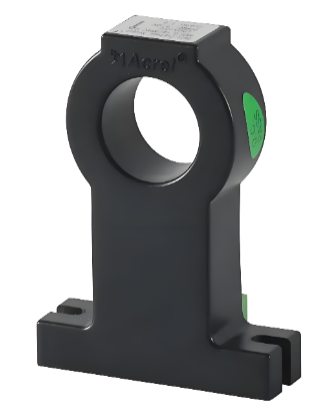

The powertrain of an electric vehicle operates at voltages ranging from 400V to 800V and beyond, presenting a critical safety challenge. Directly measuring these voltages with traditional resistive dividers would create a galvanic connection between the high-voltage battery pack and the low-voltage control system, posing a severe shock hazard to both the vehicle's electronics and occupants. This is where the inherent isolation capability of Hall effect voltage sensors becomes indispensable. Sensors like the RTV series utilize magnetic coupling to measure voltage without any electrical contact with the high-voltage line. The input voltage is applied to a primary internal resistor to generate a small current, which then flows through a multi-turn coil wound around a magnetic core. This principle provides reinforced galvanic isolation, typically in the range of several kilovolts, ensuring that any faults or transients on the high-voltage side cannot propagate to the sensitive low-voltage control unit. This isolation is the foundational layer of safety, making accurate and safe voltage monitoring possible.

2. Accurate Voltage Measurement as the First Line of Defense

Beyond providing isolation, the primary function of the Hall voltage sensor is to deliver a precise and proportional analog or digital signal representing the high-voltage DC bus voltage. This accurate measurement is the cornerstone of multiple protective functions. The Battery Management System (BMS) relies on this real-time data to monitor the state of charge and the health of the battery pack. More critically, it serves as the first line of defense against overvoltage and undervoltage conditions. During regenerative braking, the motor acts as a generator, potentially causing a sharp rise in the DC bus voltage beyond safe limits. Conversely, a fault or heavy acceleration can cause a voltage sag. The Hall voltage sensor instantly detects these deviations. If the voltage exceeds or falls below pre-programmed safety thresholds, the BMS can take immediate corrective actions, such as commanding the inverter to reduce regenerative braking power or to limit motor torque. This precise monitoring prevents electrical stress on the battery and power electronics, safeguarding their longevity and operational integrity.

3. Ensuring System-Wide Reliability and Functional Safety

The role of the Hall voltage sensor extends beyond basic overvoltage protection to encompass the broader functional safety and reliability of the entire high-voltage system. In 800V platforms, the demands on sensor accuracy and response time are even more stringent. These sensors provide the critical data needed for monitoring the insulation resistance between the high-voltage system and the vehicle chassis, a key metric for passenger safety. Their fast response is crucial for the stable control of the inverter, which depends on accurate DC-link voltage information for pulse-width modulation algorithms. Furthermore, the robust design of these sensors, capable of withstanding the harsh automotive environment including temperature extremes and vibration, ensures consistent performance over the vehicle's lifetime. By acting as a vigilant "sentinel," the Hall voltage sensor enables the BMS and other controllers to make informed decisions, preventing catastrophic failures, ensuring compliance with international safety standards like ISO 26262, and ultimately building the trust that is essential for the widespread adoption of electric vehicles.

Summary

In summary, the Hall effect voltage sensor is an indispensable "Voltage Sentinel" in electric vehicles. It provides the essential galvanic isolation for safe operation, delivers the precise measurements required for proactive overvoltage/undervoltage protection, and contributes to the system-wide functional safety and reliability that underpins the viability of modern high-voltage EV platforms.