Intelligent Power Modules (IPMs) for High-Efficiency Motor Drives and Controls

Intelligent Power Modules (IPMs) for High-Efficiency Motor Drives and Controls

The Architectural Advantage: Integration and Protection

An Intelligent Power Module (IPM) represents a significant evolution in power electronics by integrating the core components of a motor drive inverter into a single, compact package. At its heart, an IPM contains multiple high-speed IGBTs (Insulated-Gate Bipolar Transistors) or MOSFETs that function as the power switches, along with their corresponding freewheeling diodes (FRD). What truly distinguishes an IPM from a standard power module is the inclusion of a dedicated driver circuit and a suite of built-in protection features. This driver circuit is optimally matched to the IGBTs, ensuring fast and efficient switching while minimizing gate drive losses and electromagnetic interference (EMI). Crucially, the integrated protection circuitry continuously monitors for over-current, over-temperature, and under-voltage lockout (UVLO) conditions. If a fault is detected, the IPM can shut down the system within microseconds, far faster than what is typically achievable with discrete components and a microcontroller. This high level of integration simplifies design, reduces the overall component count on the PCB, and, most importantly, provides robust protection for the module and the motor it controls, thereby dramatically enhancing system reliability.

Driving Efficiency and Performance in Motor Control

The application of IPMs in high-efficiency motor drives yields substantial benefits in performance, size, and energy consumption. By co-locating the power switches and their drivers, an IPM minimizes parasitic inductance in the switching loops. This reduction is critical for achieving cleaner voltage waveforms, lower switching losses, and higher possible switching frequencies. Higher switching frequencies allow for better PWM (Pulse Width Modulation) control of the motor, resulting in smoother operation, reduced audible noise, and improved torque control accuracy—especially at low speeds. The efficiency gains directly translate into lower energy costs and reduced heat generation, which in turn allows for smaller heat sinks and a more compact overall system design. This makes IPMs exceptionally well-suited for variable-speed applications found in industrial motor drives, compressor controls in HVAC systems, and pump and blower drives. The inherent reliability and efficiency of IPMs contribute significantly to the longevity and "green" credentials of modern motor-driven systems.

Selecting the Right IPM for Your Application

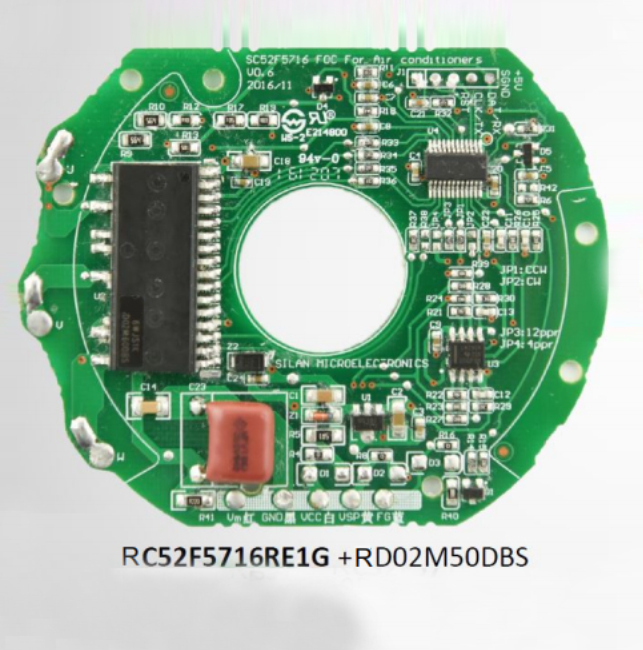

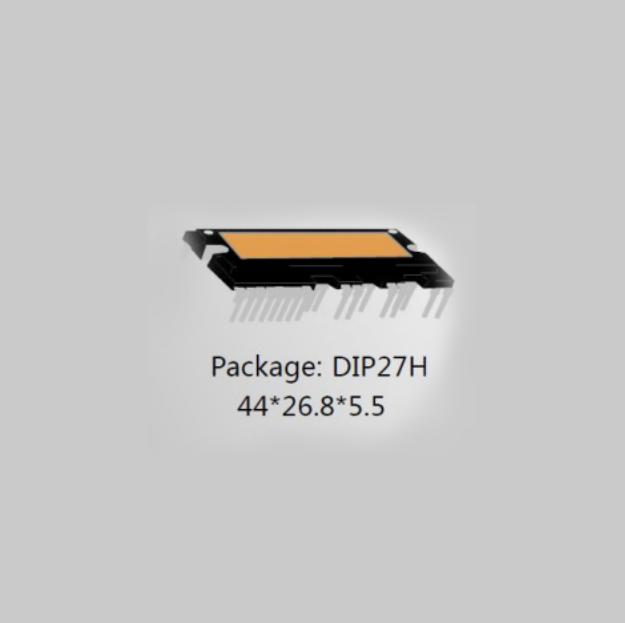

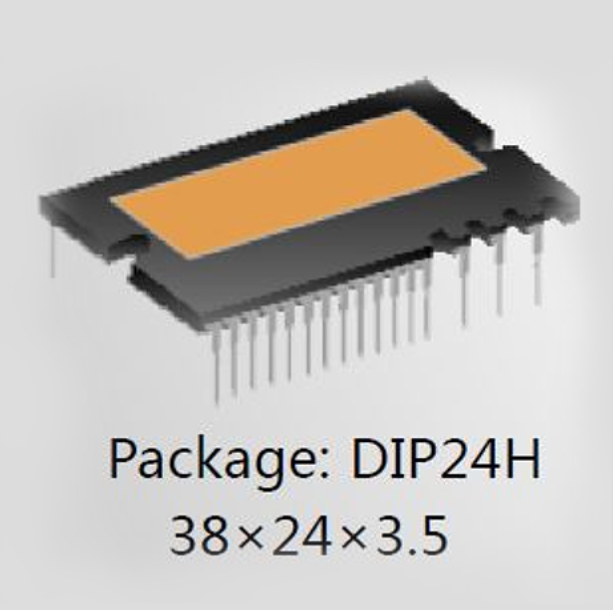

Choosing the appropriate IPM requires a careful analysis of the motor drive's specific requirements. Key parameters include the voltage rating (e.g., 600V for standard industrial applications, 1200V for higher power) and the continuous current rating, which must accommodate the motor's peak current demands. The switching speed, often characterized by the carrier frequency specification, should be matched to the application's need for quiet operation and control precision. Thermal performance is also paramount; understanding the thermal resistance of the module is essential for designing an effective cooling solution. Furthermore, the package type, such as the common DIP-IPM (Dual In-line Package) or more compact surface-mount types, must be compatible with the PCB design and assembly process. Suppliers like Rongtech Industry offer a range of IPMs, such as their DIP23 series, which are specifically designed for applications like fan and pump drives. Partnering with a manufacturer that provides comprehensive datasheets, application notes, and technical support ensures a smoother design-in process and a more robust final product.

In summary, Intelligent Power Modules are a cornerstone technology for modern, high-efficiency motor control systems. Their integrated design, which combines power switches, drivers, and protection, offers a compelling package of reliability, performance, and design simplicity. By reducing switching losses, enabling precise control, and safeguarding against faults, IPMs directly contribute to energy savings and system durability. For engineers designing motor drives for industrial, commercial, or appliance applications, selecting the right IPM from a trusted supplier like Rongtech is a strategic decision that underpins the success and competitiveness of the end product.