Features and Performance Requirements of Motor Drive Sensors

Features and Performance Requirements of Motor Drive Sensors

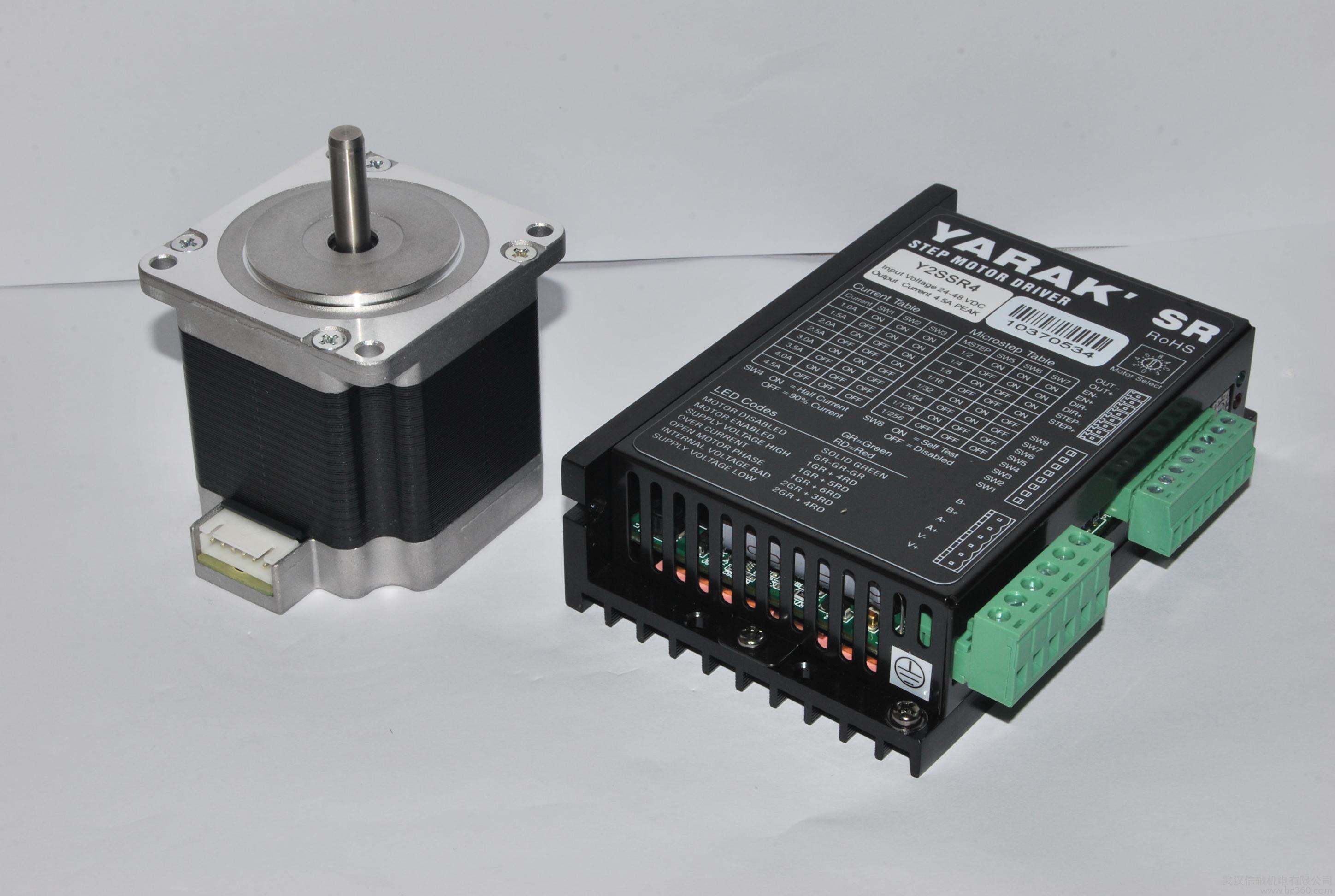

Motor drive systems, the backbone of industrial automation, robotics, and electric vehicles, rely on sensors as their "nervous system" to enable precise control, efficient operation, and fault prevention. These sensors monitor critical parameters—such as current, voltage, rotor position, speed, and torque—converting physical signals into actionable data for controllers. Below, we explore their defining features and stringent performance requirements.

Key Features of Motor Drive Sensors

Multi-Parameter Monitoring Capability

Modern motor drive sensors are designed to measure multiple variables simultaneously. For example, Hall effect current sensors track real-time current to prevent overloads, while encoders (optical or magnetic) capture rotor position and speed for closed-loop control. Some integrated sensors combine current, voltage, and temperature sensing in a single package, reducing system complexity.

Non-Contact and Contact Hybrid Designs

Non-contact sensors, such as Hall effect sensors, dominate current and magnetic field measurement. They use electromagnetic induction to detect fields without direct electrical connection, minimizing wear and tear. Contact-based sensors (e.g., resolvers) excel in harsh environments, offering robust position feedback via mechanical interaction.

Miniaturization and Integration

To fit compact motor drive units (e.g., servo drives, PDUs), sensors are increasingly miniaturized. Advanced packaging integrates Hall elements, signal amplifiers, and communication interfaces (e.g., CAN, SPI) into tiny modules, simplifying assembly and reducing costs.

Smart Diagnostics

Intelligent sensors now feature self-calibration, fault detection, and predictive maintenance capabilities. For instance, a smart current sensor can flag abnormal current spikes, alerting operators to potential motor winding faults before failure occurs.

Critical Performance Requirements

High Precision and Resolution

Precision is non-negotiable for applications like servo motors, where micron-level position control demands sensors with resolution <0.1° (for encoders) and current measurement error <0.5%. Linearity (output consistency across the full range) must exceed 99% to avoid control inaccuracies.

Fast Response Time

Dynamic loads (e.g., robotic arm acceleration) require sensors to respond within microseconds. Hall current sensors, for example, must detect current transients in <1ms to enable real-time torque adjustment, ensuring smooth motion.

Wide Dynamic Range and Temperature Stability

Motors operate under varying loads and temperatures (-40°C to 125°C in industrial settings). Sensors must maintain accuracy across a broad dynamic range (e.g., 0–500A for current sensing) and resist thermal drift, often using temperature compensation algorithms.

Robustness Against Interference

Motor drives generate strong electromagnetic interference (EMI) from inverters and switching circuits. Sensors need high EMI immunity (e.g., >60dB rejection) and shielding to prevent data corruption. Vibration resistance (up to 10g) is also critical for heavy-duty applications.

Long-Term Reliability

Industrial motors run continuously, so sensors must have a mean time between failures (MTBF) exceeding 100,000 hours. This requires durable materials (e.g., ceramic substrates for Hall elements) and protection against contaminants (dust, moisture).

Conclusion

Motor drive sensors bridge the gap between mechanical motion and digital control, with features like multi-parameter monitoring and smart diagnostics enabling next-gen automation. Their performance—defined by precision, speed, and resilience—directly dictates motor efficiency and system uptime. As industries push for higher speeds and smarter machines, sensor innovation will remain pivotal to unlocking the full potential of motor drive technology.

Google Hot Keywords: Motor drive sensor features, Hall effect sensor for motor control, encoder performance requirements, industrial motor sensor precision, EMI immunity in motor sensors, smart motor drive sensor diagnostics.