Differences and Similarities Between Closed-Loop and Open-Loop Hall Sensors

Hall sensors, leveraging the Hall effect (the generation of a voltage difference across a conductor when exposed to a magnetic field perpendicular to current flow), are pivotal in detecting magnetic fields, currents, positions, and more. Among their variants, closed - loop and open - loop Hall sensors differ markedly in architecture, performance, and applications, while sharing fundamental principles. This essay delves into their similarities, differences, and practical ramifications.

I. Core Similarities

Both closed - loop and open - loop Hall sensors depend on the Hall effect for magnetic - to - electrical conversion. Their core constituents include a Hall element (a semiconductor or metal alloy plate) and signal conditioning circuits (such as amplifiers and filters). Moreover:

Foundational Working Principle: Both identify magnetic fields by gauging the Hall voltage (, where represents the Hall coefficient, is the bias current, and is the magnetic flux density).

Application Intersection: They find use in overlapping areas like industrial automation (for position sensing), automotive systems (in electric power steering current detection), and renewable energy (such as solar inverter current monitoring).

II. Key Differences

The disparities arise from their operational architectures and design trade - offs:

1. Operational Mechanism

Open - Loop Hall Sensor: Functions in a “direct detection” manner. The Hall element directly senses the magnetic field, and the output voltage () is proportional to the magnetic flux density after amplification. There is no feedback loop to rectify errors—the output relies entirely on the Hall element’s reaction to the external field.

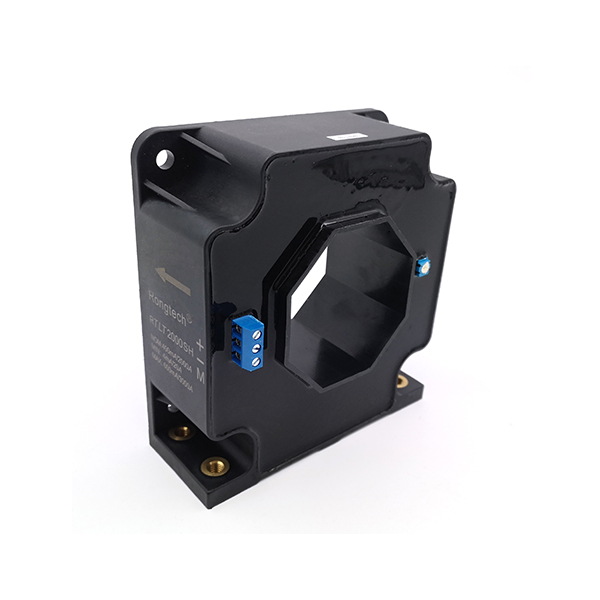

Closed - Loop Hall Sensor (also known as compensatedor flux - balancedsensors): Adopts a feedback mechanism. When the Hall element detects a magnetic field, it generates a voltage that powers a compensation coil. This coil generates a reverse magnetic field to “null” the original field, putting the Hall element at zero flux. The current in the compensation coil (or a derived signal) then stands for the measured magnetic field/current, as it balances the input field.

2. Structural Complexity

Open - Loop: Boasts a simpler design, with fewer components (Hall element + basic signal processing). This cuts down on size, cost, and power consumption, making it suitable for compact, low - cost devices.

Closed - Loop: Is more intricate, necessitating extra hardware: compensation coils, high - precision drivers, and feedback control circuits. The additional components boost size, weight, and manufacturing cost but improve accuracy.

3. Performance Metrics

Accuracy: Closed - loop sensors outshine open - loop ones due to zero - flux compensation, which eliminates nonlinearity in the Hall element, temperature drift, and external magnetic interference. Open - loop sensors are plagued by inherent errors (such as the Hall element’s nonlinearity and thermal expansion of materials).

Response Speed: Open - loop sensors react more quickly to rapid magnetic changes (for example, MHz - frequency signals) since they have no feedback delays. Closed - loop sensors, restricted by the time required to establish the compensating magnetic field, have slower response times (usually in the kHz range).

Linearity: Closed - loop sensors display superior linearity, as the feedback loop actively corrects deviations. Open - loop sensors exhibit greater nonlinearity, limiting their use in precision applications.

Temperature Stability: Closed - loop designs reduce temperature effects through feedback, ensuring stable output across wide temperature ranges. The outputs of open - loop sensors drift with temperature because of the temperature - dependent coefficients of the Hall element.

4. Frequency Response

Open - loop sensors lead in high - frequency applications (like motor speed detection and high - speed position sensing) because their direct - detection architecture avoids bandwidth limitations caused by feedback loops. Closed - loop sensors, with feedback - induced phase shifts and delays, are better suited for low - to - moderate frequency scenarios (such as power grid current monitoring).

5. Target Applications

Open - Loop: Perfect for cost - sensitive, high - frequency, or low - precision tasks:

Motor speed/rpm sensing (utilizing Hall - effect encoders).

Consumer electronics (for example, smartphone cover opening/closing detection).

Low - power current sensing (such as in battery - powered devices).

Closed - Loop: Preferred for high - precision, safety - critical, or high - power applications:

Electric vehicle (EV) battery management systems (BMS) for accurate current measurement.

Industrial servo motors (demanding precise torque control).

Grid - tied inverters and power meters (monitoring large currents with minimal error).

III. Practical Implications

Selecting between the two hinges on project priorities:

Go for open - loop if cost, size, and speed are crucial, and moderate accuracy is acceptable.

Opt for closed - loop when precision, stability, and reliability take precedence over cost and bandwidth constraints.

Google Hot Keywords for Further Research

To investigate industry trends and technical resources, consider these keywords:

“Closed - Loop Hall Sensor vs Open - Loop”

“Hall Sensor Accuracy Comparison”

“Feedback Mechanism in Hall Sensors”

“Industrial Application of Closed - Loop Hall Sensors”

“Open - Loop Hall Sensor High - Frequency Performance”

In conclusion, although both sensor types make use of the Hall effect, their architectural differences create distinct trade - offs in accuracy, speed, complexity, and cost—dictating their deployment in various technological landscapes.