Comparison between closed-loop and open-loop current sensors

Comparison between closed-loop and open-loop current sensors

The most fundamental distinction between open-loop and closed-loop (also known as zero-flux) current sensors lies in their core operating principles, both of which are based on the Hall Effect but apply it differently. An open-loop current sensor operates in a straightforward manner. The primary current (IP) flowing through the conductor generates a magnetic field, which is concentrated by a magnetic core. A Hall element placed in the core's air gap senses this field and produces a proportional Hall voltage. This voltage is then linearly amplified to provide an output voltage (VOUT). The system is "open" because there is no feedback mechanism to compensate for the magnetic field in the core. In contrast, a closed-loop current sensor employs a sophisticated negative feedback loop. It starts with the same process: the primary current generates a magnetic field sensed by the Hall element. However, the resulting signal is amplified and drives a compensation current (ICOMP) through a secondary coil wound on the same core. This compensation current generates an opposing magnetic field that seeks to cancel out (or nullify) the primary current's field. The system reaches equilibrium when the magnetic flux in the core is nearly zero, hence the name "zero-flux." The compensation current is directly proportional to the primary current, and by measuring the voltage across a precision resistor in the secondary path, a highly accurate output signal is obtained.

Performance Trade-Offs: Accuracy vs. Simplicity

The difference in operating principles leads to a direct trade-off in performance characteristics, making each type suitable for distinct applications. Closed-loop sensors are the undisputed leaders in performance. The negative feedback mechanism inherently provides exceptional accuracy, very low offset and gain drift with temperature, high linearity, and a fast response time. They are also less susceptible to saturation from high overcurrents. However, this high performance comes at a cost: they are typically larger, more complex, consume more power due to the continuous compensation current, and are more expensive. Open-loop sensors, on the other hand, excel in simplicity and cost-effectiveness. Their design is more compact, they consume significantly less power, and they are generally more affordable. The main compromises are in performance: they exhibit lower overall accuracy, higher temperature drift, and slower response times compared to closed-loop models. They are also more prone to saturation under severe overcurrent conditions. Therefore, the choice hinges on the application's priorities: if the demand is for maximum precision and stability, a closed-loop sensor is necessary; if the priority is size, power consumption, and cost for less critical measurements, an open-loop sensor is sufficient.

Optimal Application Scenarios for Each Type

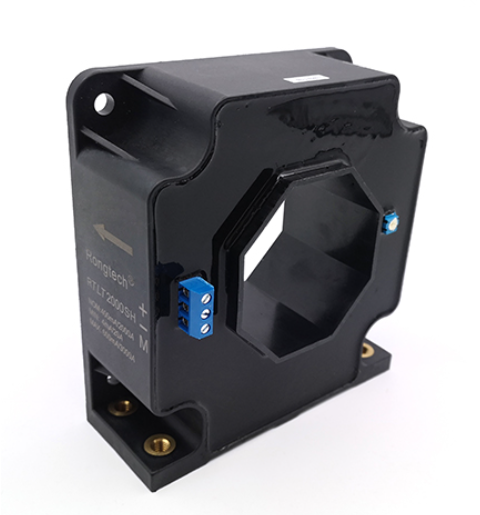

Understanding the performance trade-offs allows for clear guidance on where to deploy each sensor type. Closed-loop current sensors are the preferred choice in high-performance, critical applications where measurement precision is paramount. This includes industrial motor drives for precise torque control, advanced power quality monitoring systems, high-efficiency solar and wind turbine inverters, and precision laboratory equipment. Their ability to maintain accuracy under dynamic loads and varying temperatures is crucial in these fields. Open-loop current sensors find their strength in applications where good-enough performance is acceptable, and cost and size are significant constraints. They are widely used in variable frequency drives (VFDs) for basic current monitoring, switch-mode power supplies (SMPS), battery management systems (BMS) for state-of-charge monitoring, automotive onboard chargers (OBC), and consumer electronics. Companies like Rongtech Industry (Shanghai) Inc. typically offer robust portfolios of both sensor types, allowing designers to select the ideal solution—such as their RTC series for closed-loop needs and various open-loop models—based on the specific technical and commercial requirements of their project.

In summary, the choice between an open-loop and a closed-loop current sensor is not about which is universally better, but about which is optimal for a specific set of requirements. Closed-loop sensors offer superior accuracy, linearity, and speed at the expense of larger size, higher power consumption, and cost. Open-loop sensors provide a compact, efficient, and economical solution for applications where the highest level of precision is not critical. Engineers must carefully evaluate the priorities of their design—precision, size, power, and budget—to make the correct choice, leveraging the expertise of suppliers like Rongtech to navigate these critical trade-offs.