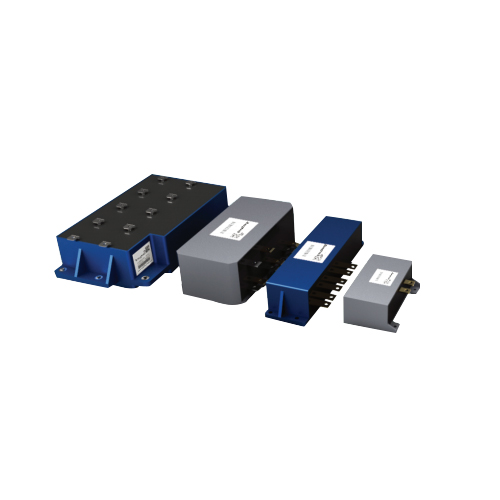

middle frequency water-cooling capacitor for induction melting

- RONGTECH

- Shanghai

- 15days

- 30000

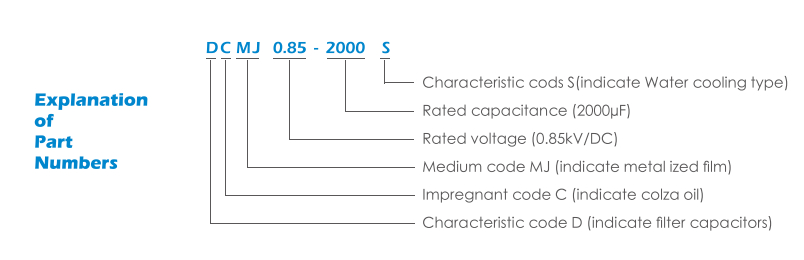

Product Scope:

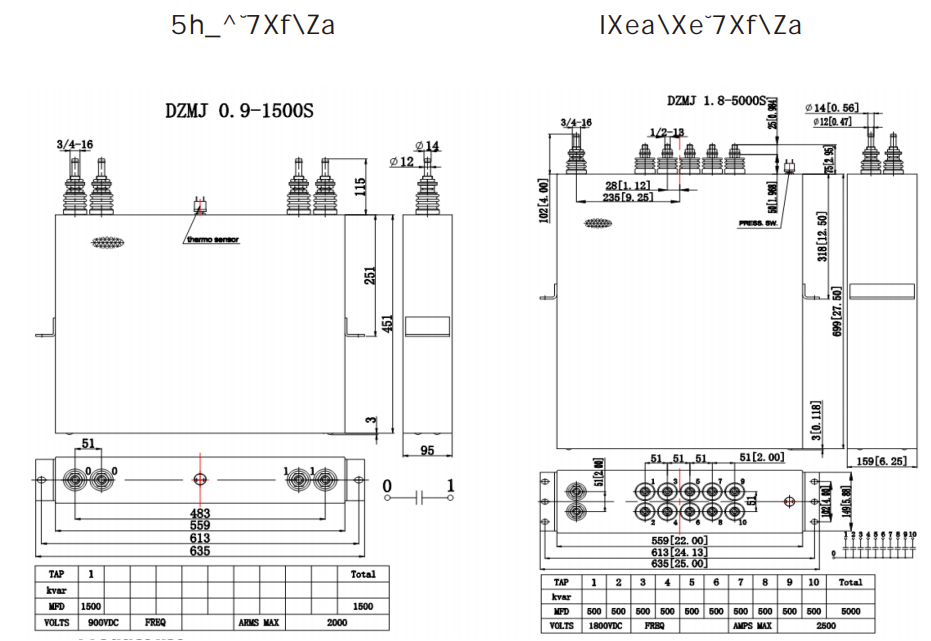

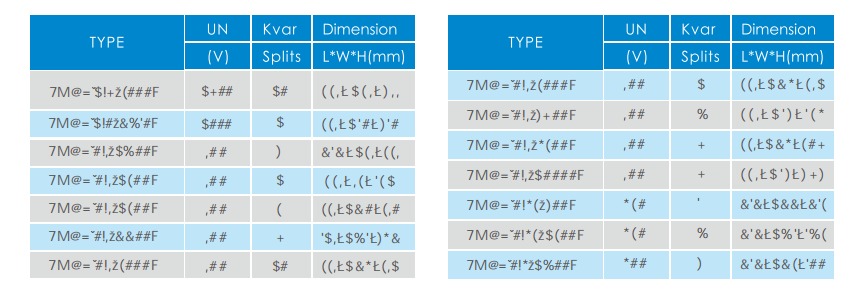

Power Range : up to 5000 μF Voltage Range : 450V to 1800V

Application:

These capacitors are designed for use on DC supplies and are intended to protect the network from momentary voltage spikes and surges and for filtering out AC ripple.

Quality Assurance System:ISO 9001:2008 ,CE

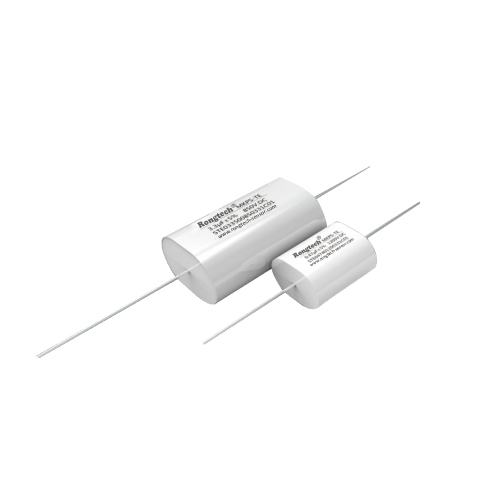

construction:

Dielectric material: metallized flmAluminum case, Side board 2mm, Cover and Base 3mm, Live or Dead case on request.Terminals material: Copper

Insulation Oil: Rapeseed oil for DC capacitors (Non- PCB, Environmentally friendly, non-toxic biodegradableMounting position: Vertically or Horizontal with proper support for the weight of the capacitor

Applications

Middle frequency water-cooled capacitors are widely used in induction heating and melting systems where high current, stable capacitance, and efficient heat dissipation are required. They are essential components in resonance circuits for medium-frequency induction power supplies, ensuring system stability, energy efficiency, and long service life.

These capacitors are commonly applied in induction melting furnaces for steel, copper, aluminum, brass, and other non-ferrous metals. They help maintain precise resonance conditions during melting, improving heating efficiency and reducing power losses. In continuous casting and billet heating lines, they ensure consistent performance under long-term high-load operation.

In induction heating systems, such as forging, heat treatment, brazing, and annealing equipment, water-cooled capacitors provide excellent current carrying capacity and thermal stability. Their efficient cooling structure prevents overheating, allowing stable operation even under frequent start-stop or rapid load changes.

They are also widely used in vacuum melting furnaces, induction holding furnaces, and medium frequency power supply cabinets, where compact structure, high reliability, and long working life are required. For special applications, customized designs can meet different voltage levels, frequency ranges, and installation environments.

Thanks to their strong insulation performance and low loss characteristics, these capacitors are suitable for harsh industrial environments, including high temperature, high humidity, and dusty working conditions. They are ideal choices for metallurgical plants, foundries, heat treatment workshops, research institutes, and induction equipment manufacturers.

Selection Notes

When selecting a middle frequency water-cooled capacitor, several key factors should be carefully considered to ensure safe, stable, and efficient system operation.

First, rated voltage and current must match or exceed the actual operating conditions of the induction system. Insufficient ratings may cause overheating, dielectric breakdown, or shortened service life.

Second, pay attention to the operating frequency range. Medium frequency induction systems usually work between 500 Hz and 10 kHz. The capacitor must be designed specifically for this frequency range to maintain stable capacitance and low loss.

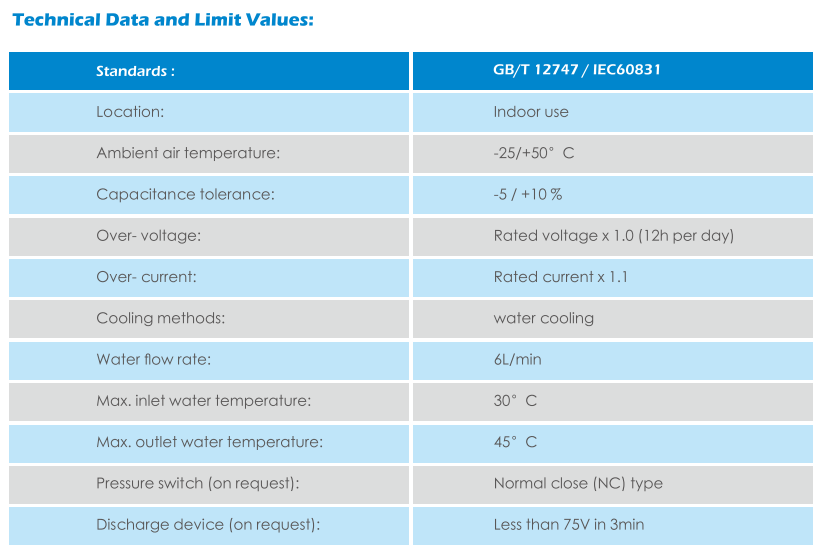

Third, cooling conditions are critical. Ensure that the water flow rate, water pressure, and water quality meet the product requirements. Clean, soft water is recommended to prevent scale buildup and corrosion inside the cooling channels, which could affect heat dissipation and reliability.

Fourth, consider the capacitance tolerance and stability. High-quality capacitors provide stable capacitance values under temperature changes and load fluctuations, which is essential for maintaining resonance accuracy.

Fifth, evaluate the installation method and space requirements. Different systems may require horizontal, vertical, or customized mounting structures. Make sure the selected capacitor fits the equipment layout and allows convenient maintenance.

Sixth, check the insulation performance and safety standards. The product should meet international electrical safety requirements and provide sufficient insulation distance to prevent electrical discharge.

Finally, for complex or special induction systems, it is strongly recommended to choose customized capacitors according to your technical parameters, such as voltage, current, frequency, cooling method, and installation conditions. Professional technical support can help optimize system performance and extend equipment life.

When choosing the right medium frequency water-cooled capacitor for your induction melting system, please refer to the key parameters and considerations below:

No. | Consideration Factor | Details / Recommendations |

|---|---|---|

1 | Voltage Rating | Select a capacitor with rated voltage between 450V – 1800V that matches or exceeds your system’s operating voltage to ensure safety and reliability. |

2 | Capacitance Value | Choose capacitance based on system power and resonant frequency design. Our range supports up to 5000 μF for various medium frequency applications. |

3 | Cooling Method | These capacitors are water-cooled. Ensure your system provides proper water flow, temperature control, and uses clean/deionized water for cooling. |

4 | Mounting Orientation | Can be installed vertically or horizontally, but must be properly supported to avoid mechanical stress or deformation. |

5 | Ambient Environment | Suitable for industrial environments. Uses non-toxic, biodegradable rapeseed oil insulation. Ensure normal temperature and avoid corrosive conditions. |

6 | Terminal Connections | Equipped with copper terminals. Ensure your wiring and connection method match the terminal size and current rating to prevent loose contact. |

7 | Quality & Certifications | Compliant with ISO 9001:2008 quality system and certified with CE mark, ensuring high reliability, safety, and international performance standards. |

? Tip: For customized solutions or technical assistance, please consult Rongtech’s engineering team. We’re happy to help you select or design the optimal capacitor for your specific induction melting system.