The Trade-offs in Motor Drives: Open-Loop vs. Closed-Loop Hall Sensors - A Deep Dive into Cost, Accuracy, and Bandwidth.

The Trade-offs in Motor Drives: Open-Loop vs. Closed-Loop Hall Sensors - A Deep Dive into Cost, Accuracy, and Bandwidth.

1. The Simplicity and Cost-Effectiveness of Open-Loop Hall Sensors

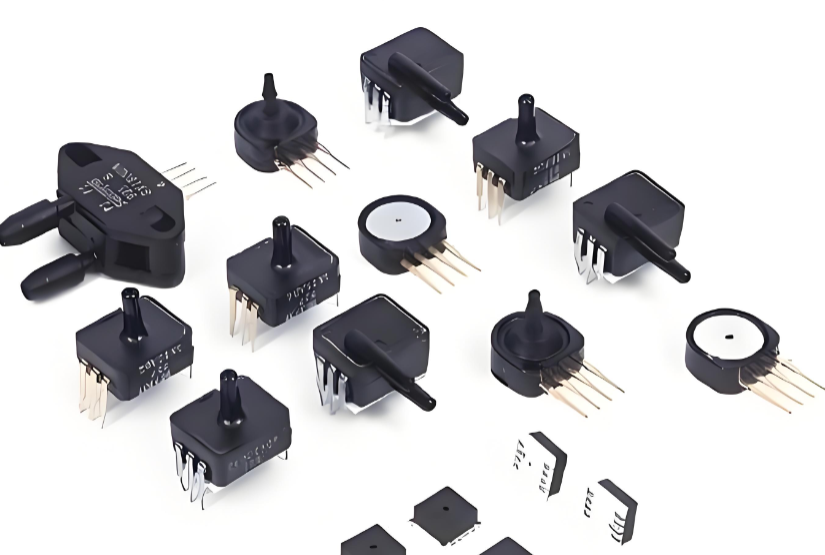

Open-loop Hall effect current sensors operate on a straightforward principle: a Hall element is placed in a magnetic field generated by the current flowing through a conductor, and the resulting voltage output is directly proportional to the measured current. This simple architecture, requiring no additional feedback components, makes open-loop sensors like the RTB series inherently cost-effective and compact. They are an excellent choice for applications where space and budget are primary constraints, and where extreme precision is not critical. However, this simplicity comes with inherent trade-offs. The output of the Hall element is susceptible to the nonlinearities of the magnetic core and is significantly influenced by temperature variations. Without a mechanism to compensate for these factors, the accuracy and linearity of open-loop sensors are lower compared to their closed-loop counterparts. They are typically suitable for measuring DC, AC, or pulsed currents in scenarios where a potential error of 1-3% is acceptable, such as in general-purpose inverter control or basic motor overload protection.

2. The High Performance and Precision of Closed-Loop Hall Sensors

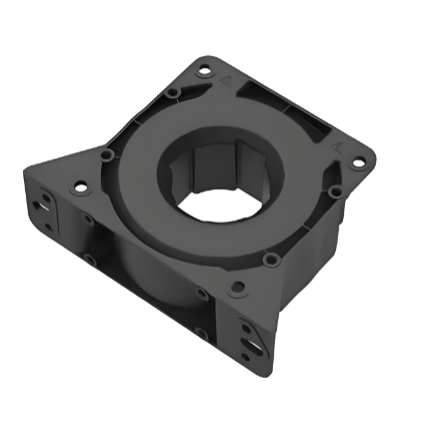

Closed-loop Hall sensors, also known as "zero-flux" sensors, incorporate a sophisticated feedback mechanism to achieve superior performance. Similar to the open-loop type, they use a Hall element to sense the magnetic field. However, the Hall output is amplified and drives a compensation coil wound on the same magnetic core. This coil generates a counter-acting magnetic field that precisely cancels out the primary field generated by the measured current. The system operates in a state of equilibrium ("zero flux"), and the compensation current required is an exact representation of the primary current. This active feedback loop, found in sensors like the RTC series, effectively neutralizes the effects of core nonlinearities and temperature drift, resulting in exceptional accuracy (often as high as 0.1%), excellent linearity, and a very fast response time. This makes them indispensable for high-performance applications like precise servo motor torque control, where accurate current feedback is crucial for dynamic response and smooth motion.

3. Critical Application-Specific Trade-offs: Bandwidth, Power, and Cost

The choice between open-loop and closed-loop technologies hinges on a detailed analysis of the application's specific requirements against the system's constraints. The key trade-offs are in bandwidth, power consumption, size, and cost. While closed-loop sensors offer high bandwidth and fast response, their feedback loop can introduce a slight propagation delay, and they require a continuous supply of power for the compensation circuit, leading to higher power consumption and internal power loss. Open-loop sensors, being passive in nature, consume very little power. The most significant differentiator often remains cost. The complex design and additional components of closed-loop sensors make them a more premium solution. Therefore, the selection criteria are clear: for cost-sensitive, less demanding applications where good performance is sufficient, the open-loop sensor is the ideal choice. For high-performance motor drives, precision instrumentation, and applications demanding the highest levels of accuracy, stability, and speed, the investment in a closed-loop Hall sensor is justified and necessary.

Summary

In conclusion, the selection between open-loop and closed-loop Hall current sensors is a fundamental engineering decision centered on balancing performance needs with economic reality. Open-loop sensors offer a compelling solution of simplicity and low cost for mainstream applications. In contrast, closed-loop sensors deliver unparalleled accuracy and speed for demanding, high-performance motor drives, justifying their higher cost. Understanding these trade-offs empowers designers to optimize their systems for both performance and value.