The "Muscles" and "Senses" of Industrial Robots: How Motor Drive and Sensor Technologies Enable Precise Movement.

The "Muscles" and "Senses" of Industrial Robots: How Motor Drive and Sensor Technologies Enable Precise Movement.

1. The "Muscles": Precision Motor Drives and Power Electronics

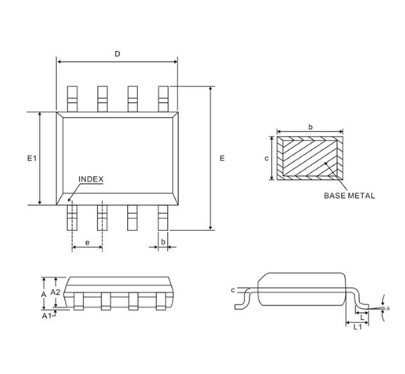

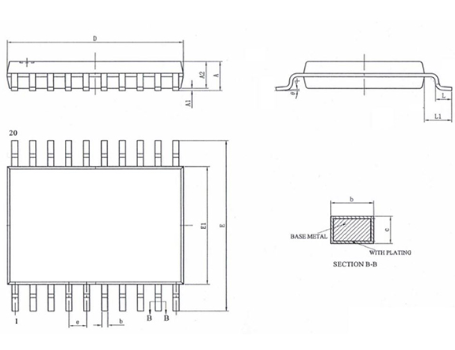

The physical movement of an industrial robot—its "muscles"—is orchestrated by advanced motor drive systems, predominantly comprising servo motors controlled by sophisticated power electronics. These systems, including Intelligent Power Modules (IPMs) and dedicated Power Driving ICs, are responsible for converting control signals into precise amounts of electrical power to drive the motors with exceptional accuracy. IPMs integrate key components like IGBTs or MOSFETs with built-in protection features (e.g., under-voltage lockout, over-current protection, and short-circuit protection), ensuring robust and reliable operation. The role of these power modules is critical; they must switch high currents rapidly and efficiently to control the torque and speed of each joint motor. The precision of this power delivery directly influences the robot's ability to perform tasks requiring high repeatability, such as arc welding or precise assembly. The efficiency of these drives, often enhanced by wide-bandgap semiconductors like SiC MOSFETs, also minimizes heat generation, allowing for more compact robot designs and reducing the burden on cooling systems.

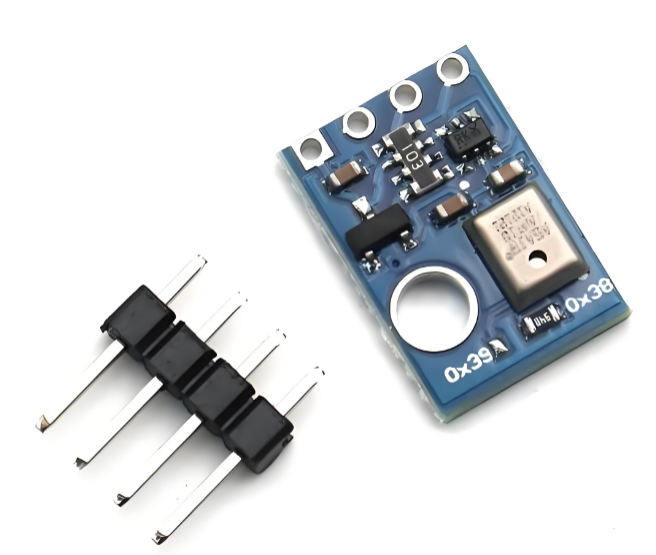

2. The "Senses": Real-Time Feedback from Current and Position Sensors

For movement to be precise, the robot's control system requires constant, accurate feedback—this is the role of its "senses." High-precision sensors provide the real-time data necessary for closed-loop control, creating a continuous feedback cycle between the robot's actions and its controller. Hall-effect current sensors, both open-loop and closed-loop, are indispensable here. They continuously monitor the current flowing to each motor, providing an instantaneous measure of torque. This allows the controller to make micro-adjustments, ensuring the motor delivers exactly the required force without overshooting or lagging. Furthermore, encoders (e.g., optical or magnetic) attached to the motor shafts deliver precise information on angular position and velocity. This sensory combination tells the controller not just how much force is being applied ("sensed" by current sensors), but also exactly where the joint is located and how fast it is moving ("sensed" by encoders). This high-fidelity feedback is what enables a robot to perform delicate tasks like handling fragile objects or following a complex contour with unwavering accuracy.

3. The Synergy: Closing the Loop for Unmatched Precision and Reliability

The true magic of robotic movement lies in the seamless synergy between the "muscles" and "senses." The motor drive system and sensors work in concert within a high-speed closed-loop control system. The controller sends a command signal to the drive electronics (the "muscles") to move a joint to a specific position. As the motor responds, the current and position sensors (the "senses") instantly feed data back to the controller. The controller compares this real-time data with the intended command. If there is any deviation—for instance, an unexpected resistance causing a drop in speed or an increase in torque—the controller immediately adjusts the power output from the drive modules to correct the error. This continuous cycle of action, sensing, and correction happens thousands of times per second. It is this dynamic feedback loop that compensates for variables like friction, inertia, and changing payloads, enabling the exceptional repeatability, path accuracy, and reliability that modern industrial robots are known for. The quality and speed of these components, such as fast-responding Hall sensors and low-loss IPMs from manufacturers like Rongtech, are fundamental to achieving this high level of performance.

Summary

In conclusion, the precise and dexterous movement of industrial robots is not the result of a single technology but a deeply integrated system. The "muscles"—comprising robust motor drives and power electronics—provide the physical force, while the "senses"—high-precision current and position sensors—deliver the critical feedback. Their synergy within a high-speed closed-loop control system is what transforms individual components into a dynamic, intelligent, and highly accurate motion system, driving automation to new levels of efficiency and capability.